HIGH PRESSURE SYSTEM

This transportation system uses high-pressure compressed air. Its structure is not much different from that of the low pressure system. But because it uses an -head-air apparatus such as an air compressor to generate high pressure (approximately 2~5kgf/㎠) for transportation, the system stores the material in tanks designed for high pressure, such as the Transporter, and transports it. Compressed air is forced into the Transporter, where the transport material becomes pressurized. An Aeration Nozzle is installed at the lower part of the system to control the mixture rate, and an Air Booster is partially installed on the conduit line to maintain the fluidity of air in order to transport the mixture of material and air. For the head-air apparatus that are generally required for the above system, an air compressor or reciprocating type air compressor is used. This is because of the high air pressure and low amount of air, and this has an advantage for installation of small dust collectors

PRECAUTIONS RELATED TO THE HIGH PRESSURE SYSTEM

Since the transportation is carried out in the high pressure receptacle in an empty vacuum, full and regular continuous transportation may not be possible. (In this situation, the continuous system will incorporate a hopper for temporary storage in the central front of the unit.) Powder can be transported directly from the high-pressure receptacle, but large particles are transported in the receptacle of the unit with a Rotary Feeder or Clipper attached.

APPLICATIONS

Long distance transportation of a large amount of materials (Food, petrochemicals, rubber products, etc.)

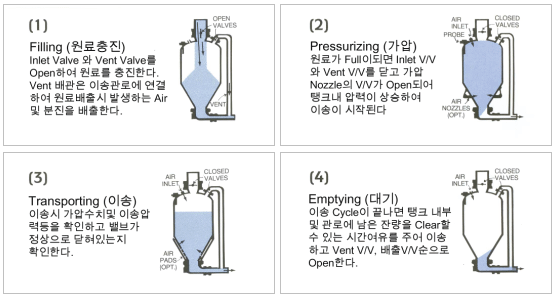

[Transporter Operation]

MEASUREMENT AND DISCHARGE OF MATERIAL FOR THE HIGH PRESSURE SYSTEM

A certain amount of material is discharged from the lower part of the Silo or Tank to other transporting devices, put into the meter for high precision measurement and discharged to the high pressure system for transportation. There is another method of transportation that does not require the installation of an independent meter, but involves attaching Load Cell to the High Pressure System itself and then measure for transportation.

PVC & CaCO3 POWDER HANDLING

This equipment transports raw materials by using high pressure-compressed air and is mixing the equipment which stores PVC power and CaCO3 on the bottom of a silo to mixing equipments of the inside facility by right amount accumulating or a separate measuring. By installing an air booster at the transport conduit to minimize clogging effect and it will help to transport smoothly. By installing a storing hopper which has a filter at the rear part of the transport conduit, do first mixing work by air and a raw material distribution and discharge with liquid additive and secondary raw material mixing. Also the secondary transport is putting into Banbury mixer after transporting to the bottom of transporter followed by a raw material storing and a measuring.

- CONVEYING CAPACITY (POWDER) : 3500Kg/HR

- MIXING CAPACITY : 4500Kg/HR

- STORAGE VOLUME : 120 ㎥- 2 SET, 100㎥-2 SET

EXAMPLE OF A HIGH PRESSURE SYSTEM INSTALLATION

- SILO FOR MATERIAL STORAGE

The silo installed on the system is a Skirt type, and was manufactured to store PVC and CaCO3 materials. (Storage capacity: 2 units of 120㎥, 2 units of 100㎥) - TRANSPORTER

A device to supply high-pressure air generated in the compressor through an Air Receiver Rank and Dryer to the Transporter Air Nozzle and Air Booster installed in the conduit line for transportation in a fluid condition. The high-density, rapid transportation approach enables the transport of a large amount of materials in a short period of time. However, continuous transportation is difficult due to its closed-type batch transportation. (But continuous transportation is possible when designed in a bilateral high pressure system) - BAG FILTER CYCLONE

This can be manufactured in small sizes, as it uses less air than the Blower type transportation system - RIBBON BLENDER

Manufactured in a Jacket type. Through controlling the outer temperature using high-temperature steam, the system transports and mixes powder and liquid through a secondary transporter. - AIR COMPRESSOR

Screw compression types and cylinder types can be selected after precise design, considering transportation pressure and the amount of air involved in the process.

- MAIN CONSTRUCTION ITEM

- - Storage Silo

- - Transporter (High Pressure Vessel)

- - Air Compressor & Dryer, Air Receiver

- - Bin Activator

- - Control Panel