VACUUM SYSTEM

The Suction-type air transport has a head-air apparatus installed at the rear of the system to transport the powder from the starting point of the conduit line. At the starting point of the transport system, a filtering device is installed to prevent the entry of foreign substances. At the rear of the system, a classifier is installed to discharge transported materials in the air. The most frequently used head-air apparatus are ROOTS, TURBO, and FAN BLOWER. Compared to other transport types, this system features easy installation and allows concentrated transportation to 1 destination from multiple systems. It provides the benefits of a low price and easy installation.

PRECAUTIONS ON THE SUCTION-TYPE SYSTEM

Because of the limits on practical suction pressure, the distance and amount of transportation cannot be increased at the same time as either of the two is restrained. If the transported substance contains dust, it is necessary to install a dust collector in front of the head-air apparatus. As the head-air apparatus takes in and transports pressurized air, the system tends to become larger and thus is more expensive.

APPLICATIONS

Raising crops in ship and transporting food, chemicals, crops, toxic materials, etc.

PVC HANDLING

This equipment transports chemical materials, and the head-air apparatus should be installed at the rear of the equipment to transport, measure, and mix materials to produce raw materials for products.

The main material is PVC, and measuring is possible immediately after transportation. The equipment minimizes measurement deviations for the accurate manufacturing of products.

Working time can be reduced, as liquid materials can be measured immediately after transport. The time required for transportation measurement and discharge is 3 to 5 minutes, which allows for separate work.

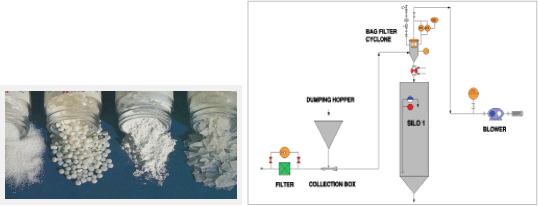

The main device consists of a Silo, head-air apparatus (Blower), and Meter, which are the basic components of the suction-type system. The meter enables direct measuring or other measuring work by using other measuring devices, depending on space restrictions and/or installation placement.

EXAMPLES OF SUCTION-TYPE SYSTEM INSTALLATION

- SILO FOR MATERIAL STORAGE

The silo installed at the main unit is the Skirt Type for the storage of PVC and CaCO3 materials. - MEASURING HOPPER (BAG FILTER CYCLONE)

Load Cell (Meter) is attached to detect the weight of the transported material, and the filter and air pulse-type dust collecting devices are installed in the upper part. - COLLECTION BOX

Allows control of the amount of material taken in and the caliber of discharge, so that the material is discharged into the Silo and is proportionate to the amount of suction. - SUPER MIXER

Measures and discharges material such as plasticizer and mixed materials and mixes them. - ROOTS BLOWER (for suction-type systems)

Material transportation distance, pressure, and the material amount are all considerations in installations.

- MAIN CONSTRUCTION ITEM

- - Storage Silo

- - Collectoin

- - Riquid T/K